Product Information

QT4-15 automatic brick production line introduce

|

A |

QT4-15 Host brick machine |

|

B |

Block receiver |

|

C |

Stacker, it could layer 4-5 pallets blocks |

|

D |

6m conveyor |

|

E |

JS500 Mixer bigger power, 25.1KW |

|

F |

Batching machine PLD 800, power, 9KW |

|

Color feeder system |

QT4-15 Color feeder machine--Automatic hydraulic machine |

|

Color mixer--1.2m; 7kw |

|

|

6m conveyor |

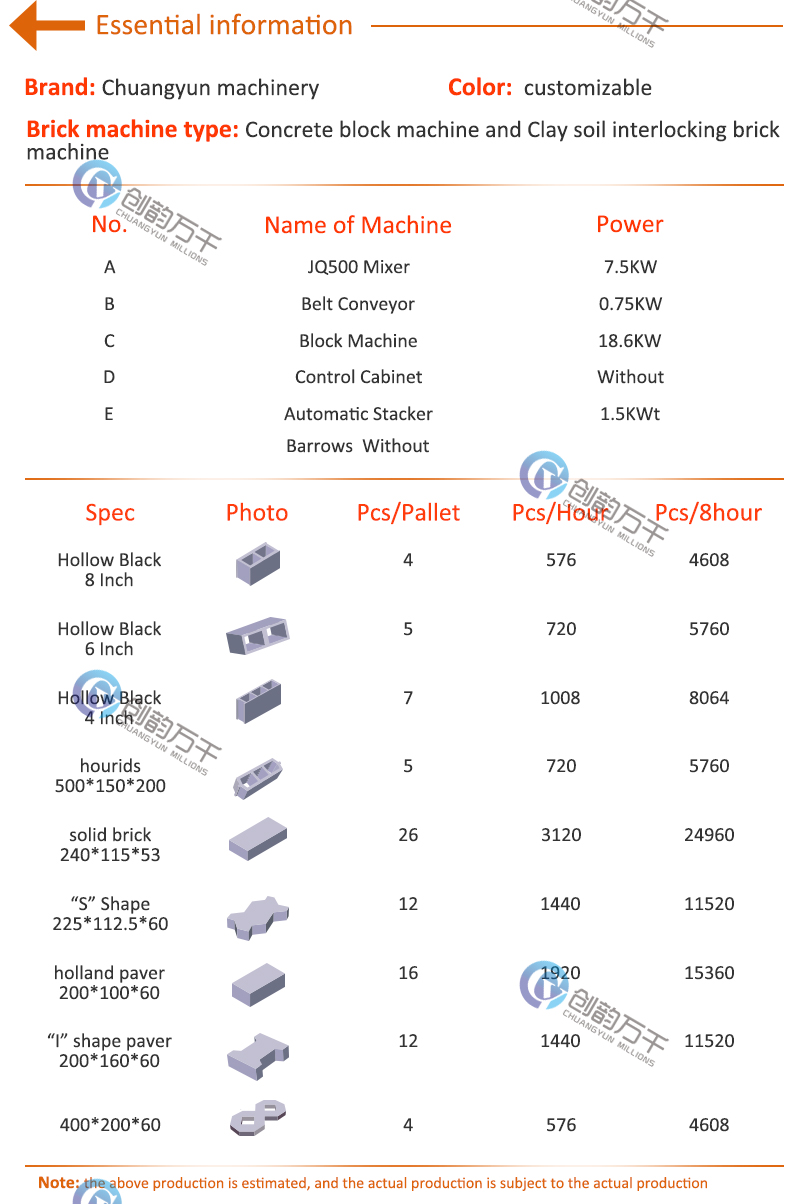

QT4-15 Automatic brick plant technical information:

|

QT4-15 Host machine total power |

22.2KW |

|

Molding cycle |

15s |

|

Host brick machine size |

3740*2230*2450mm |

|

Pallet size |

960*550mm |

Concrete hollow block production process

1. Techinical Specification of related machines.

A. PLD800 Batching Machine

|

Item |

PLD800 Batching Machine |

|

Hopper Store Capacity |

2500L*2 |

|

Productivity |

38M3/H (dry material) |

|

Power |

9KW |

|

Batching Accuracy |

+_2% |

|

Fedding Height |

3000MM |

|

Maximium Weight |

2000KG |

|

Machine Size |

5600*1950*3000mm |

|

Machine Weight |

3500KG |

B. JS500 Mixer

|

Item |

JS500 Mixer |

|

Feeding Capacity |

800L |

|

Discarging Capacity |

500L |

|

Productivity |

23-28M3/H |

|

Speed of Stirring Shaft |

23r/min |

|

Mixing Power |

18.5KW |

|

Lifting Hopper Speed |

25m/min |

|

Max. diameters of Aggregates |

60/80mm |

|

Stirring Time |

30-35 Seconds |

|

Mixer Size |

3400*2300*2700mm |

|

Mixer Weight |

4000KG |

|

Wather Pump Motor |

0.55KW |

C.QT4-15 Automatic block making machine

|

Item |

QT4-15 Automatic Block Machine |

|

Power |

26.45KW |

|

Moulding Cycle |

15-18 Seconds |

|

Vibration Froce |

70KN |

|

Pallet Size |

960*550*20mm |

|

Machine Size |

4000*1800*2800mm |

|

Machine Weight |

5000KGS |

|

Workshop |

200M2 |

2. Production Capacity of QT4-15 automatic hydrulic cement brick block making machine

QT4-15 automatic hydraulic cement brick block making machine can produce sizes of hollow block, solid brick, interlocking paver, hourdis and curbstone by changing molds.

|

Item |

Block |

Production capacity |

Photo |

|

1 |

Hollow/Solid block 400-200-200mm |

4 pcs/mold |

|

|

2 |

Hollow/Solid block 400-150-200mm |

5 pcs/mold |

|

|

3 |

Hollow/Solid block 400-100-200mm |

7 pcs/mold |

|

|

4 |

Houdi S block 450-120-200mm |

5 pcs/mold |

|

|

5 |

S shape paver 225-112.5-60mm |

12 pcs/mold |

|

|

6 |

I shape paver 200-160-60mm |

10 pcs/mold |

|

|

7 |

Holland paver 200-100-60mm |

14 pcs/mold |

|

the following are some designs of blocks and pavers for your reference:

3.Block instruction

Material Ratio for Blocks

a: 10% Cement, 30% Sand and 60% Stone

b: 10% Cement and 90% Stone Powder

c: 10% Cement, 30% Fly Ash and 60% Stone Powder

Material Consumption

We take 400*200*200mm hollow block as example and 10% cement in Raw Material

|

Size of Block |

400*200*200mm |

|

Photo of Block |

|

|

Capacity |

7608 blocks in one day |

|

Material Ratio |

10% Cement, 90% sand and Stone |

|

Consumption of Cement |

11520 KG in one day |

|

Consumption of Stone |

103680 KG in one day |

4.Advantage of QT4-15 automatic hydraulic concrete brick block making machine

A: Automatic PLC Operation, Big Capacity, Low Labour Cost

B: Hydraulic Press, High Strength of Block and Paver

C: Produce sizes of hollow block, solid brick, hourdis, paver and curbstone by changing molds.

D: Suitable for Large and Medium-scale Block Factory

4. Photos of QT4-15 automatic hydraulic block machine test for Cong

QT4-15 Automatic concrete block making machine in Kenya

CYUN QT4-15 cement block brick making machine in Ecuador

CYUN QT4-15 hydraulic block machine in Ghana