1.Wheel loader can be used to transport the sand and aggregate to the concrete batching machine.

2.The batching machine adopts the most advanced pressure measurement method in China, and are equipped with the function of automatic drop correction and compensation;

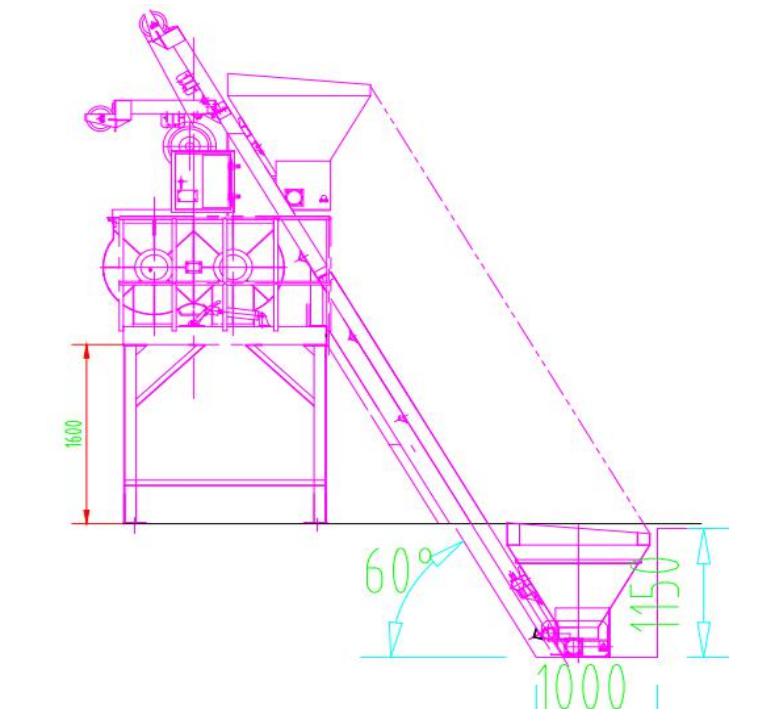

The belt conveying has the advantages of long conveying distance, large capacity, continuous conveying, etc. very convenient

3.Add the weighed additives, aggregate, powder, and water will be mixed evenly in the twin shaft concrete mixer. Planetary mixer also good.

4.After the stipulated time, the concrete mixture will be discharged to the block machine through a belt conveyor;

5.Cement silo can replace civil construction silo, with waterproof, moisture-proof, prevent cement loss and environmental pollution. It’s featured in all footprint, cost saving and long service life.

1. The computer adopts the domestic famous brand industrial computer, which is simple to operate and easy to master.

2. The weighing is accurate, the response is fast, and the dynamic panel display can clearly understand the operation of each component.

3. It can store and print report data.

Mixers

Mixers are at the core of every plant. Just like mixing cookie dough, Making good cookies requires consistency and proper mixing of all the ingredients. Want help determining which method of materials measuring is best for your application? Email me at with your questions and I’ll walk you through it. Use this link to get your answers.

TWIN SHAFT

Producers use Twin Shaft Mixers are normally companies which are wanting to mix large quantities of concrete in volume at high speed and have equipment that is long lasting with low operating cost and maintenance. The twin shaft mixers are most commonly used in the Pre-stress and Ready mix industries.

The mixer tank is lined with Mangaloy hardened and wear resistant liners and blades The unique aspect of the twin shaft mixing action is the large number of blades, their position and orientation during the high speed circulation of the material during the mixing action.

| Model | Charging Capacity (L) | Discharging Capacity(L) | Productivity( mз/h) | Aggregate Size(cobble/gravel) (mm) | Overall Dimension(LXWXH) (mm) |

| JS500 | 800 | 500 | 25 | 80/60 | 4486x3030x5280 |

| JS750 | 1200 | 750 | 35 | 80/60 | 5100x2250x6700 |

| JS1000 | 1600 | 1000 | 50 | 80/60 | 8765x3436x9540 |

| JS1500 | 2400 | 1500 | 75 | 80/60 | 9645X3436X9700 |

| JS2000 | 3200 | 2000 | 100 | 80/60 | 3500X2320X1677 |

| JS3000 | 4800 | 3000 | 150 | 80/60 | 3990X2600X1700 |

| JS4000 | 6400 | 4000 | 200 | 120/100 | 4450X3050X2380 |

Planetary

Planetary mixers use a special type of pan mixer to offer short mix times and vigorous mixing for quick and uniform batches.

How Do Planetary Mixers Work?

CYUN planetary concrete mixers are designed to produce concrete of extraordinary quality at high speeds. Every planetary mixer’s frame is constructed to be stronger than virtually any other type of mixer in the industry, granting them incredible dependability.

With such a strong and massive body frame, planetary mixers’ multi-star mixing action provides the fastest and most complete mixing of full-sized batches. As an added benefit, the intense mixing action that a planetary mixer offers will save you money on your cement costs.

Batching Controls

Cyun offers a full range of batching control systems to meet the demanding requirements of today's concrete industry. With the latest technology including: graphical user interface that is easy to operate, Compact Logix PLC and Panel View Plus HMI for optimal performance and prewired controls cabinet to reduce installation time and costs. Whether you operate a small masonry plant or a multiple mixer Precast operation, CYUN Machine has a safe and reliable batching controls solution to fit your needs.

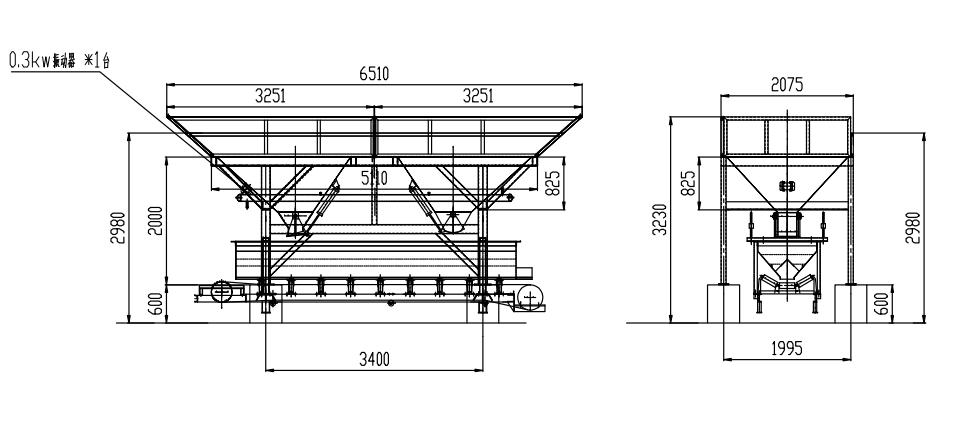

CYUN Batching Solutions offers a complete line of aggregate bins, conveyors, truck hoppers, delivery systems and electronics to meet almost any aggregate handling requirement.

Features

Easy to use batch and mix recipe designer

Graphical sequencer for mix optimization

Pop-up screen navigation for easy set up of controls

Volumetric and weighed aggregate batching

Scalable system for single and multiple mixer operations

Colored concrete blending recipes

Multiple safety zone control

SQL database with web access for recipes and records

Remote operation through smart tablet devices

Retrofits into existing batch plants

Material Handling

Fly Ash & Cement Storage Silos with automatic weighing

There is an endless amount of different materials we have built silos for material storage but the most common are list below. We are ready to customize for you if your material is different.

MATERIALS

- Cement Fly Ash

- Lime

- Coal

- Color Pigments

- Bottom Ash

- Aggregates

- Frac Sand

A complete one stop solution is offered here. If you are needing a complete custom plant built with aggregates bins, weigh belts systems, concrete mixer and total plc control automation, call or email today to further discuss you plant design.