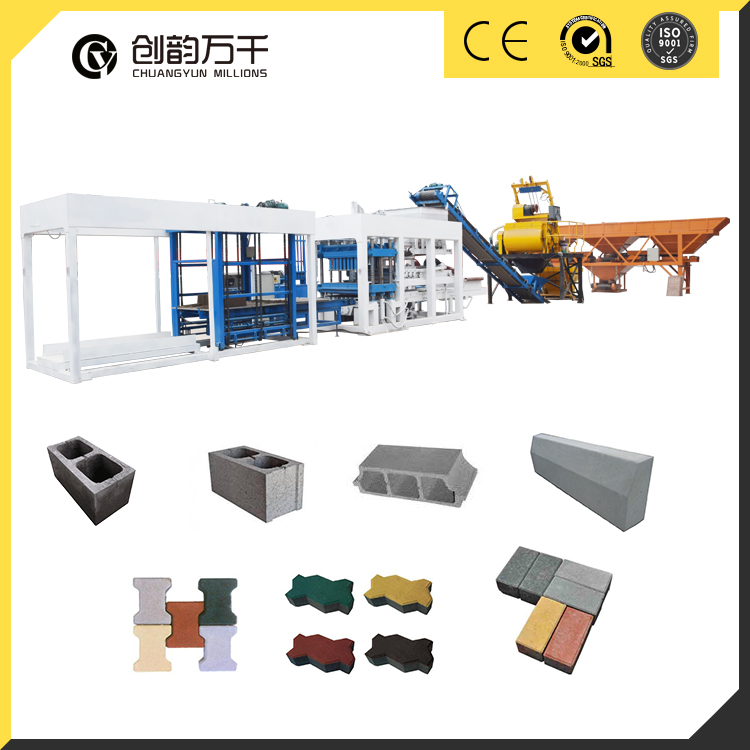

Product Information

1. Advatanges QT10-15 automatic concrete block making machine

A: Automatic PLC Operation, Big Capacity

B: Hydraulic Press, High Strengh of Block and Paver

C: Produce Sizes of Hollow block, Solid Brick, Paver and Curbstone by changing molds

D: Suitable for Large-scale Block Factory

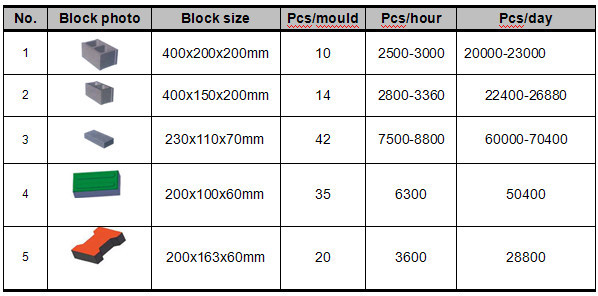

2.Produciton Capaicty of QT10-15 fully automatic concrete block making machine

QT10-15 fully automatic hydraulic block making machine can produce sizes of hollow block, solid brick, paver and curbstone by changing molds. the following are production capacity for some popular sizes of blocks and pavers.

3. Detailed Introduction of QT10-15 automatic hydraulic concrete cement block making machine

A:Electricity Power of QT10-15 automatic hydraulic block making line

|

NO. |

Item |

Power |

Function |

|

A |

PLD1200 batching Machine |

12KW |

Automatic Batching raw material |

|

B |

JS750 Mixer |

38.6KW |

Mixer Raw Material |

|

C |

Pallet Lifing Machine |

5.2KW |

LIfting pallet into pallet box of block machine |

|

D |

8m Belt Conveyor |

1.1KW |

Carry mixed matrial from mixer to block machine |

|

E |

QT10-15 Block Machine |

45.5KW |

automatic material feeding system automatic pallet feeding system hydraulic station automatic PLC control |

|

F |

Block Sweeper |

2.2KW |

Carry fresh block from block machine to stacker |

|

G |

Automatic Stacker |

3KW |

Automatically stacking fresh block with 4-5 pallet |

|

Total Power:108.7KWEelctricity must be 3 phase, 50/60HZ, 380V/440V/220V |

|||

Features of Our QT10-15 Automatic Block Making Machine

Germany technology was adopted and well combined with our domestic design, which ensure the machine with leading technology. It’s well approved that this machine can be really practical during building projects or block factory equipment. And there is no concern that this machine can be used for even 10 years. The strict technological requirement ensure the machine good quality, stable and reliable performance, long working life time and high efficient work. The products are high strength, large density and low cost.

1. Material and Welding: Using the High-Strength Steel and Carbon Dioxide Protection Welding assuring CYUN brick making machine stable running.

2. Vibration System: Mould vibration plus table vibration

A: provides more vertical vibration at the starts of the cycle which aids in compaction of the material in the molds and potentially reduces feed time

B: Higher speeds can provide a better product finish.

C: the ability to decrease speed of stripping of product can reduce culls and aids in the manufacture of hard-to -form products such as thin-walled block

D: Reduces horizontal mold movement during machine cycles for longer mold life

3. Mould Structure: We design the mould structure specially in order to change the mould easily and we use the new Heat Treatment and Carbonization to diffusing carbon into the Surface of steel. It will increase Hardness, Wear-resistance of the Surface of Mould, While Maintaining toughness and strength of the core of Mould. So our Block Mould is more stronger and twice life than ordinary mould.

Photos of QT10-15 Automatic Hydraulic Block Making Machine

QT10-15 automatic hydraulic block making machine in production

Mexico Customer test QT10-15 Automatic hollow block making machine